1. Product introduction

DJ-Z series mechanical diaphragm metering pump (GM diaphragm metering pump) is mainly a reciprocating metering pump, which can be divided into single cylinder, double cylinder, three cylinder and other types according to the number of cylinders

2. Product pictures

3. Scope of application

GM diaphragm metering pump is widely used in petroleum, chemical industry, metallurgy, mining, shipbuilding, light industry, electric power, printing and dyeing, environmental protection, water treatment, food and beverage industry, military industry, etc

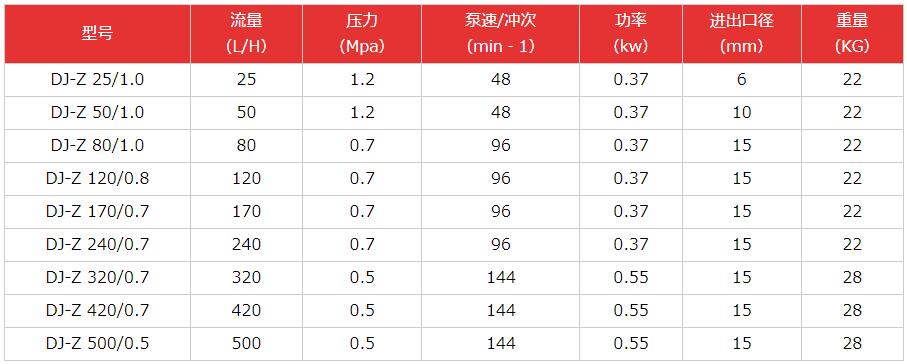

4. Specifications

Note: 1. If the parameters are different from those in the table during the model selection process, our factory can improve the model selection through technology.

DJ-Z mechanical diaphragm metering pump: Installation, Storage, Maintenance, and Operation Guide

The DJ-Z Mechanical Diaphragm Metering Pump is a high-precision pump engineered for accurate liquid dosing in industrial, chemical, and water treatment applications. Its robust mechanical diaphragm design ensures consistent, pulsation-free flow with precise control over discharge volumes. This guide provides detailed instructions on installation, storage conditions, maintenance routines, and operational procedures, offering a comprehensive reference for engineers, operators, and procurement professionals.

The DJ-Z diaphragm pump is widely used in industries requiring precise dosing of corrosive, viscous, or high-purity liquids, including:

Chemical processing plants

Water and wastewater treatment

Industrial manufacturing lines

Pharmaceutical and food industries

Mechanical Diaphragm Design: Ensures high-accuracy dosing and minimal pulsation

Durable Construction: Resistant to corrosion and wear, suitable for aggressive fluids

Adjustable Stroke and Flow Rate: Allows precise control for varying operational requirements

Energy-Efficient Operation: Optimized mechanical design reduces power consumption

Low Maintenance: Easy access to replaceable components

Proper installation is essential for safe, efficient, and reliable operation of the DJ-Z pump.

Verify the pump and driver compatibility (motor or manual drive).

Ensure the installation area is dry, well-ventilated, and free of debris.

Check that all piping connections are clean and free of obstructions.

Inspect mechanical components for any visible damage during shipping.

Mounting: Secure the pump to a rigid base to minimize vibration and noise.

Alignment: Ensure proper alignment of the pump drive with the motor to prevent mechanical stress.

Piping Connections:

Connect inlet and outlet pipes using appropriate fittings.

Install valves as required to control flow and allow isolation for maintenance.

Priming: Fill the pump with compatible liquid to avoid dry running.

Leak Test: Before full operation, check all joints and connections for leaks.

| Task | Recommended Action |

|---|---|

| Base Mounting | Rigid, level surface to reduce vibration |

| Piping | Clean, aligned, and correctly sized |

| Drive Alignment | Check motor-pump alignment before operation |

| Priming | Fill pump with fluid to prevent diaphragm damage |

| Leak Test | Operate briefly to inspect for leaks |

Proper storage extends the pump’s service life and prevents premature wear.

Store in a dry, ventilated, and clean area.

Maintain ambient temperature between 5°C and 40°C, avoiding freezing or excessive heat.

Protect from dust, moisture, and direct sunlight.

Rotate the diaphragm or pump shaft periodically to prevent component seizure.

Inspect seals, gaskets, and moving parts before recommissioning after storage.

| Component | Storage Recommendation |

|---|---|

| Pump Body | Covered or packaged to prevent dust accumulation |

| Diaphragm | Periodically rotated or flexed to avoid deformation |

| Seals & Gaskets | Inspect before operation |

| Motor/Drive | Protected from moisture and corrosion |

Regular maintenance ensures consistent performance, reduced downtime, and long service life.

| Task | Frequency | Purpose |

|---|---|---|

| Visual inspection | Weekly | Check for leaks, vibration, and noise |

| Diaphragm check | Monthly | Detect wear or cracks to prevent failure |

| Valve and seal inspection | Every 3–6 months | Ensure proper sealing and prevent leakage |

| Lubrication (if applicable) | Every 3–6 months | Reduce friction in moving parts |

| Performance testing | Annually | Verify flow accuracy and pressure stability |

Use genuine spare parts to ensure compatibility and reliability.

Flush the pump after handling corrosive or sticky liquids to prevent buildup.

Keep a logbook of operational parameters and maintenance activities.

Monitor for unusual vibration, noise, or changes in flow rate as early warning signs.

Correct operation ensures accuracy, safety, and efficiency of the DJ-Z pump.

Confirm pump and motor are properly mounted and aligned.

Verify the suction and discharge valves are correctly positioned.

Ensure fluid supply is sufficient to avoid dry running.

Inspect electrical connections (if motor-driven) for safety.

Open the suction valve and partially open the discharge valve.

Activate the pump, gradually increasing the speed if adjustable.

Monitor pressure, flow, and diaphragm movement for normal operation.

Close the discharge valve slowly to avoid pressure spikes.

Turn off the motor or drive.

Flush the pump with clean water or compatible fluid to remove residual chemicals.

Record operational parameters and any anomalies for future reference.

Disconnect power before performing maintenance.

Wear appropriate protective equipment when handling hazardous fluids.

Do not operate the pump outside the recommended flow rate and pressure ranges.

The DJ-Z mechanical diaphragm metering pump is widely used in industrial, chemical, water treatment, and food production applications.

Chemical Dosing: Accurate addition of acids, alkalis, and other reactive chemicals.

Lubricant Transfer: Smooth delivery of oils and high-viscosity fluids.

Adhesives and Resins: Precise volumetric dosing in production lines.

Chlorine and Disinfectant Dosing: Safe and precise chemical dosing for water purification.

pH Control: Accurate addition of neutralizing chemicals.

Syrups and Pastes: Smooth, clog-free transfer for food production.

Medicinal Solutions: Accurate dosing in pharmaceutical manufacturing.

Hygienic Operation: Stainless steel wetted parts suitable for cleanroom environments.

The DJ-Z Mechanical Diaphragm Metering Pump offers precision, reliability, and durability for industries requiring accurate fluid dosing. By adhering to recommended installation procedures, storage conditions, maintenance routines, and operational guidelines, users can ensure long service life, consistent performance, and minimal downtime.

Whether used in chemical plants, water treatment facilities, or food and pharmaceutical manufacturing, the DJ-Z pump provides safe, pulsation-free, and energy-efficient metering, making it a trusted solution for high-demand industrial applications.

Phone:+86 15868545868/+8618968868555

whatsapp:+86 15868545868/+8618968868555

Email:haiwan@haiwanpump.cn

Add:Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Copyright ? 2025 Zhejiang Haiwan Pump Industry Co., Ltd.